Automated Storage and Retrieval Systems (AS/RS)

Maximizing storage space and increasing the flow of non-palletized and palletized products and inventory is critical to the continued success of virtually any warehouse or order fulfillment operation. Automated storage and retrieval systems (AS/RS) combine a variety of types of equipment and technologies to quickly and efficiently retrieve required items and materials with reduced manual labor.

If you’re looking for a partner capable of delivering AS/RS solutions to help you meet your throughput objectives and storage needs, turn to BlueSkye Automation as a turnkey provider for all your needs. Our knowledgeable and experienced team will be happy to provide cost-effective solutions that help grow your business.

Partnering with Leading Technology Companies:

Benefits of Automated Storage and Retrieval Systems

With the rapid advancement of technology and the introduction of new products and systems on the market, automated storage and retrieval systems have become an integral tool to remain competitive in warehousing and order fulfillment. An effective AS/RS virtually eliminates the need for large storage areas and automates repeatable tasks of storing and retrieving items in your facility.

There are many advantages of installing an Automated Storage and Retrieval System:

- Reclaimed floor space

- Expanded production capabilities

- Increased throughput

- Lower dependency on labor

- Faster and more accurate order picking

- Increased quality control and product safety

- Better ergonomics and reduced workplace injuries

- Improved inventory control and optimization

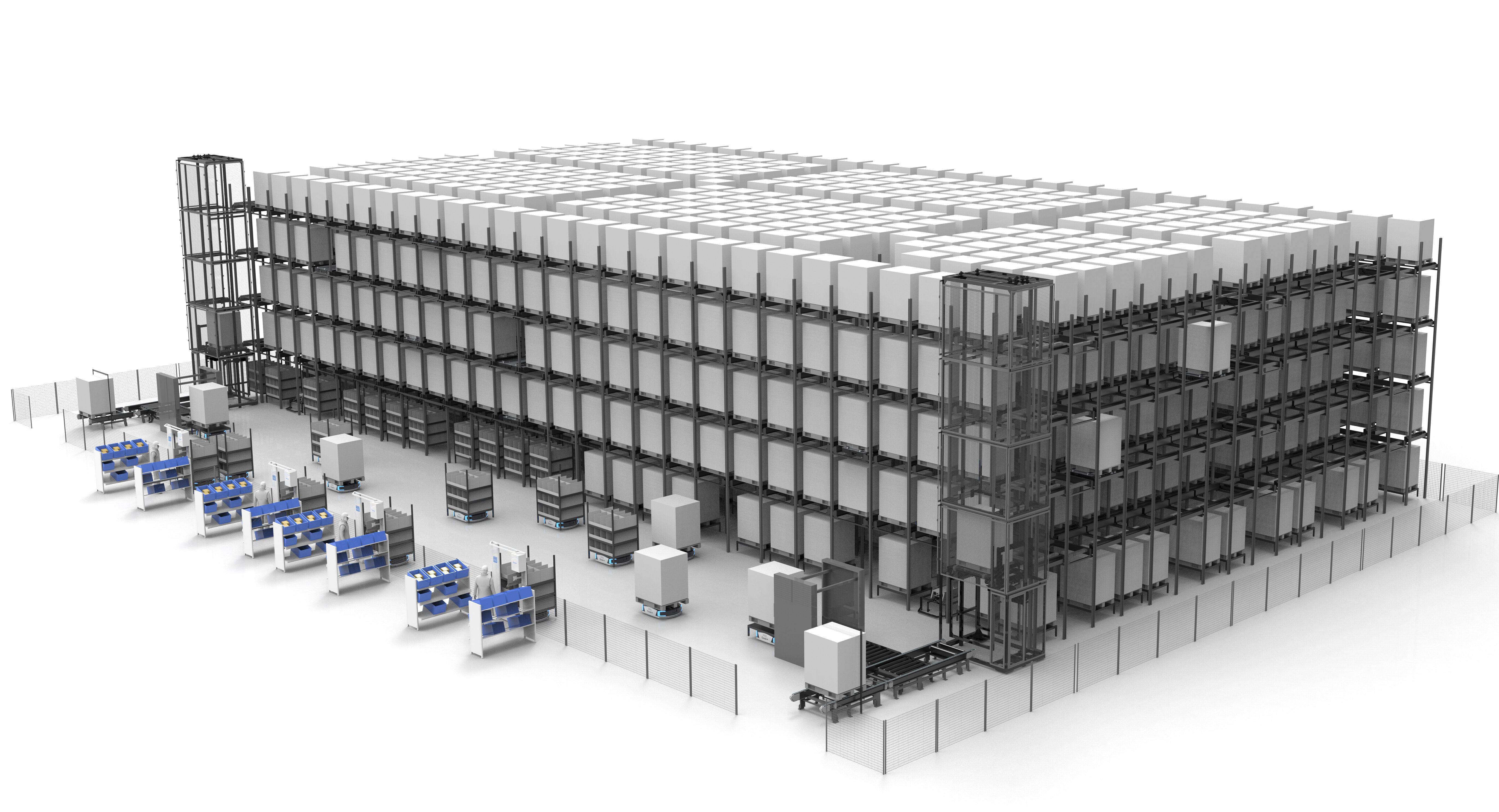

SkyCube Pallet-to-Person AS/RS

SkyCube is an innovative, multilevel storage-and-retrieval system (AS/RS) integrating upper-level vertical pallet storage and ground-level picking technology. The solution increases warehouse throughput, storage capacity, operational flexibility, and can integrate with intelligent equipment (such as an an automated forklift, automatic wrapper or packer, robotic arm for palletization/depalletization) to realize a fully automated smart warehouse. The SkyCube is a 4-way shuttle AMR that rides rails inside a pallet racking system. The shuttle is able to automate inbound, storage and outbound of pallets saving up to 60% aisle space vs. a traditional static racking system. SkyCube offers an industry unique combination of shelf to person solution at floor level with vertical racking above provides efficient handling and storage of eaches, cases and pallets all-in-one system.

Key features:

- 2600 pound payload capacity

- Moves at speeds up 3.5 mph

- Improve storage density up to 5-8x vs. traditional picking solutions

- Boosts picking efficiency up to 300% with improved accuracy vs. a manual warehouse

- No single point of failure, scalable

- Fast return on investment (ROI) typically < 3-years: space savings, less labor, faster picking/throughput

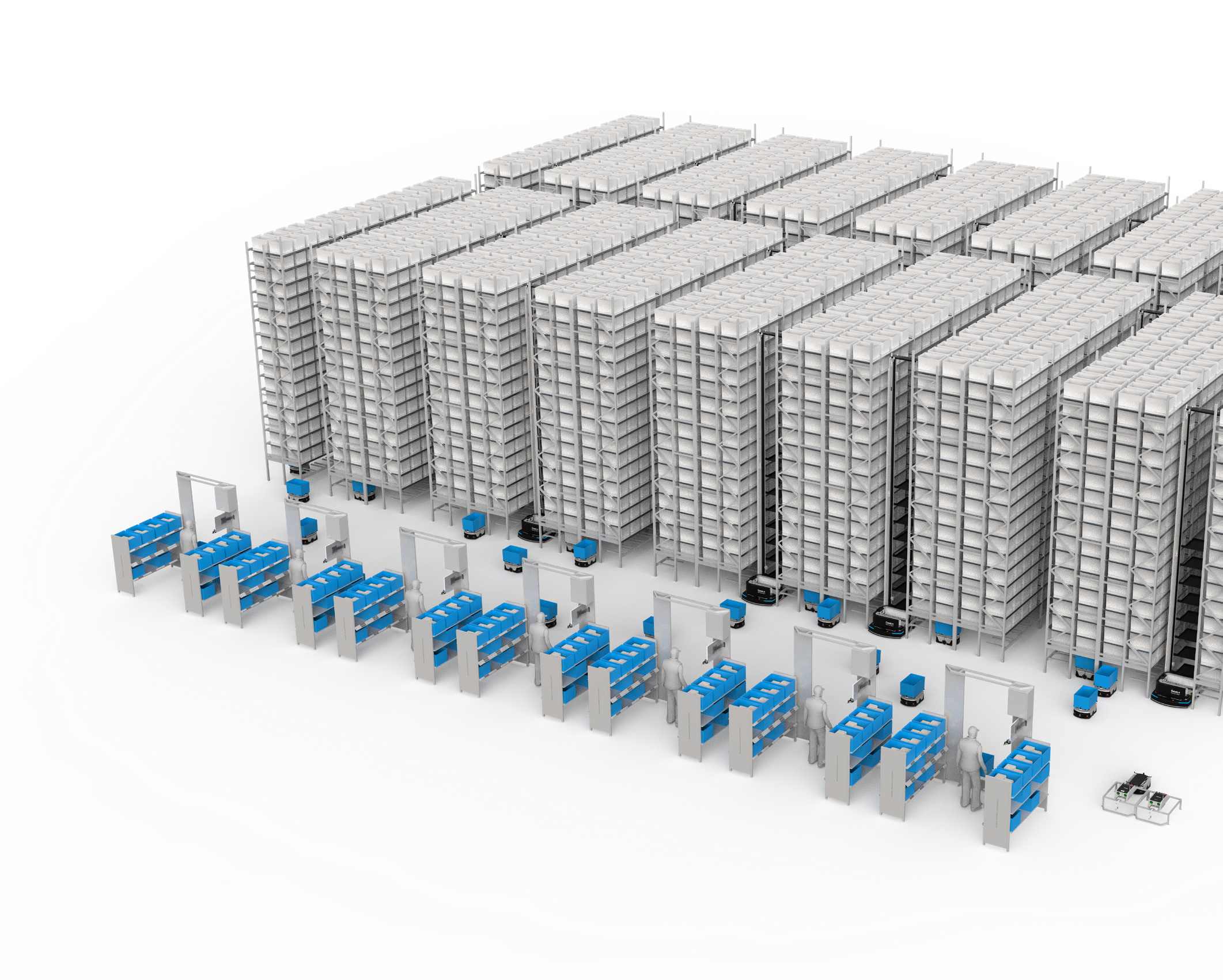

RoboShuttle Tote-to-Person AS/RS

The RoboShuttle Tote-to-Person order fulfillment mobile robot solution combines double-deep vertical warehouse storage with high picking throughput. Two robots work together: one that goes high for tote storage and retrieval, and one that goes fast for order picking and replenishment. The RoboShuttle robot is a tall, high density storage robot compatible with multi-size totes and cartons. It’s double deep storage functionality helps maximize aisle space. The P40 robot is a fast tote-carrying robot equipped with a lifting module that adjust the tote to a suitable ergonomic height for operators. RoboShuttle tote-to-person solutions can be combined with shelf or pallet to person solutions in one operational area to provide a solution that meets your dense storage and fast picking needs.

Key features:

- 88 pound payload capacity

- Increases storage density using vertical space up to 35′ tall

- Flexibility to handle multiple tote and case sizes in 1 system

- Retrieval System (RS) moves at speeds up 4 mph and P40 moves at speeds up to 10 mph

- Combine with shelf to person solution to efficiently handle eaches, cases and pallets in 1 system

- Boosts picking efficiency up to 350 totes/hr/station with improved accuracy

- Scalable, with fast ROI typically within 1-3 years

Partnering with BlueSkye Automation for AS/RS Solutions

We offer integrated solutions designed to solve your new and existing warehouse operating challenges. Our team takes a comprehensive approach to getting to know your operation inside and out. We provide a detailed upfront consultation and thorough assessment of your existing systems. As a turnkey provider, we offer expert system design and mechanical and electrical engineering and installation as well as software implementation, documentation and training, and on-site and post-implementation support.

At BlueSkye Automation, we work with leading warehousing, inventory, storage and distribution systems management technologies. Additional reasons to choose us as your AS/RS vendor include:

- Excellent customer service, communication and responsiveness

- Creative design abilities to deliver the most economical and practical solutions

- Significant domain experience and desig engineering expertise

- A trusted and reliable company that partners with leading automation companies that offer the latest in advanced robotics

Get in Touch Today

Unlock the full potential of your operation with AS/RS solutions from BlueSkye Automation. Contact us for more information.